-

Contact Sales

Contact Sales

We will contact you in a timely manner

-

Service Hotline

Service Hotline

400-112-1280

-

More contact information >

More contact information >

Solution Overview

Solution Overview

As the first automation control product launched by SynMatic based on the automotive electronics design concept, the integrated controller for water tank wire drawing machines is specifically tailored for the wet drawing process in the wire and cable manufacturing industry and metal products (including steel cords and steel wire ropes). This controller achieves a revolutionary volume reduction, which is more than 90% smaller than traditional electrical control cabinets, reducing costs by over 50%. At the same time, it significantly improves the protection level to completely eliminate the fault hazards caused by metal powder to the electrical control system, ensuring continuous and stable production. This solution also solves multiple pain points in the industry:

Space and heat dissipation: The electrical cabinet solution dissipates heat into the air, leading to higher workshop temperatures. Besides, the electrical cabinet occupies a large space.

Maintenance: There are high requirements for maintenance personnel in fault locating and troubleshooting.

Traditional electrical cabinets do not support the distributed I/O system, and can be upgraded to support this solution through programming or hardware replacement.

Traditional electrical cabinets support asynchronous motors or permanent magnet synchronous motors only.

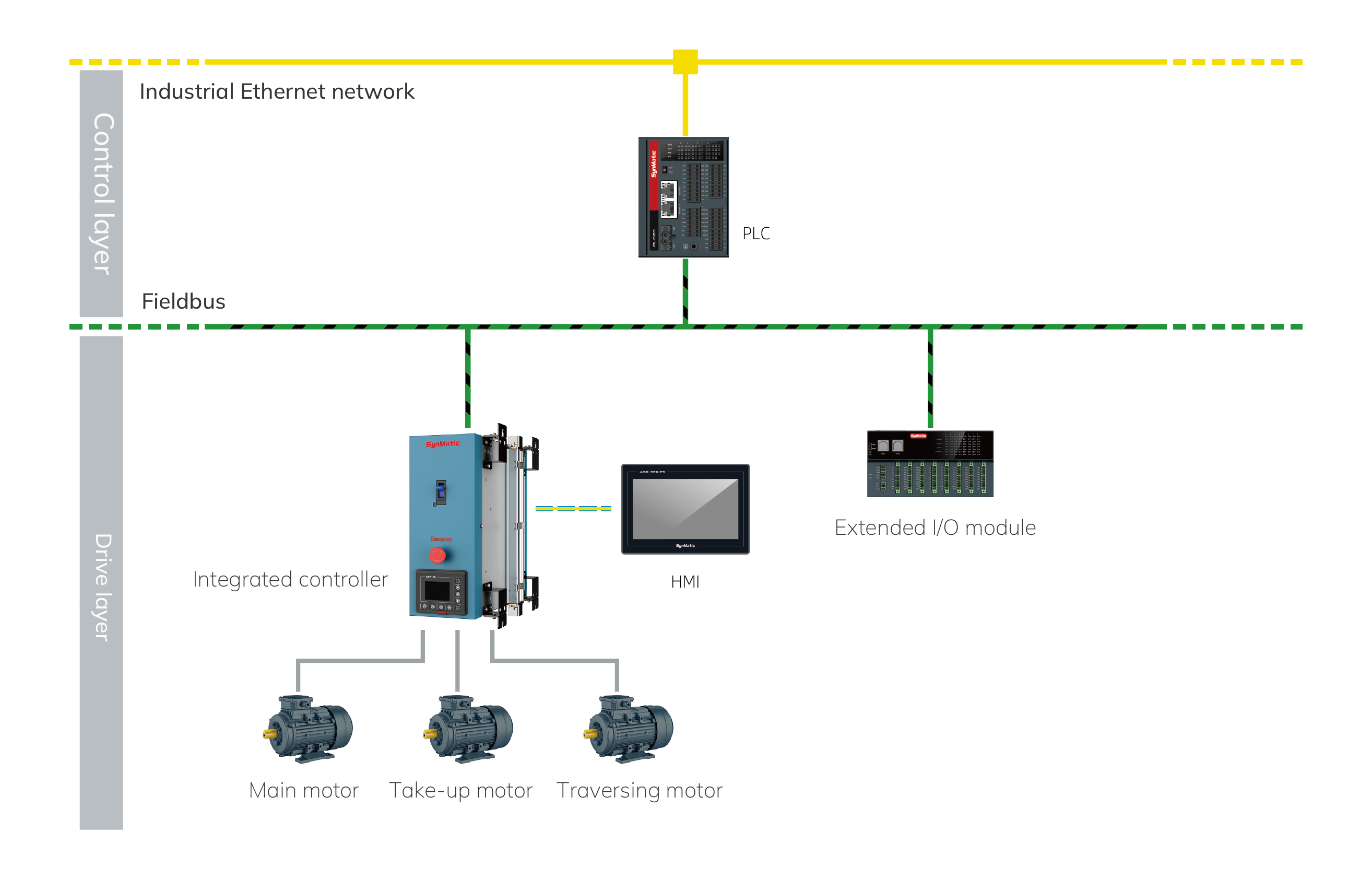

Solution Topology

Solution Topology

Solution Advantages

Solution Highlights

Enhanced safety and stability

Wire drawing lubricant cooling solution: Adopts a non-negative pressure design inside electrical cabinets to effectively prevent intrusion of metal powder and significantly improve the system safety and stability, providing protection for the production environments.

Improved space and heat dissipation efficiency

Integrated compact design: Greatly reduces the device volume and dissipates heat through the circulation of lubricant to achieve dual improvements in efficient space utilization and heat dissipation performance, optimizing the production environments.

Convenient maintenance

Fault prompt: Prompts faults on the screen to quickly locate the faults and reduce the troubleshooting time.

Modular design: Adopts a three-board modular design inside to facilitate quick replacement and maintenance, reducing maintenance costs.

One-touch operations: Supports one-touch commissioning and parameter copying through the operating panel to improve efficiency.

Enhanced device connection scalability and compatibility

Self-developed distributed I/O technology: Reduces the wiring complexity between the motor and the take-up mechanism, requiring only power cables and communication cables.

Diverse built-in algorithms: Supports various process techniques such as traverse compensation, cone disc traversing, and double-wire/triple-wire take-up.

Wide compatibility: Provides built-in algorithms for various types of motors such as asynchronous motors, permanent magnet motors, and reluctance motors, and switches among the algorithms through the function codes.

Comprehensive adaptability: Is suitable for various water tank wire drawing machines and can process multiple types of materials such as wire and cable, enameled wire, steel cord, steel wire rope, stainless steel wire, alloy wire, and iron wire.

Related Products

Related Products

Contact Sales

Contact Sales

We will contact you in a timely manner

Service Hotline

Service Hotline

400-112-1280

More contact information >

More contact information >