-

Contact Sales

Contact Sales

We will contact you in a timely manner

-

Service Hotline

Service Hotline

400-112-1280

-

More contact information >

More contact information >

Product Highlights

01

Performance optimization

Builds faster, stabler, and more accurate drive scenarios.

Shorter communication cycle: The full series is equipped with high-performance main control units to provide faster communication through the EtherCAT protocol. An ultra-short synchronization cycle of 125 μs is supported.

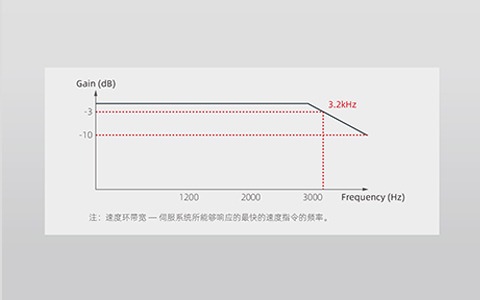

Faster dynamic response: The speed loop bandwidth of 3.2 kHz shortens the positioning and tuning time.

High positioning accuracy: This product integrates high-resolution encoders and precision calibration and uses advanced control algorithms to achieve stable and precise motor control.

Smaller synchronization jitter: Through precise regulation with EtherCAT distributed clocks, the synchronization error is only 15 ns and the jitter is ±20 ns for 300 nodes within a distance of 120 m.

Low-frequency jitter suppression: The jitter suppression function is optimized to simultaneously suppress two types of low-frequency jitters at the device end, improving device stability and production efficiency.

High-frequency vibration suppression: Five groups of notch filters (two groups of adaptive notch filters and three groups of manual notch filters) are configured to effectively suppress vibrations with simple operations, improving product performance.

02

Ease-of-use

Significantly improves the usability with the sophisticated and novel design.

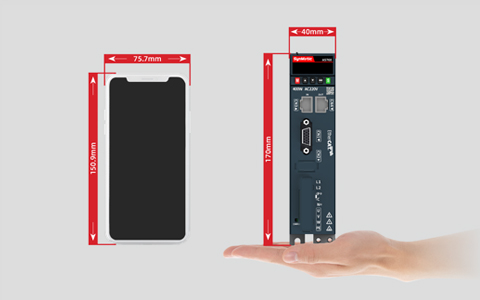

Low space requirements: Boosting a compact structure, this product adopts next-generation power devices and an innovative design to significantly reduce the overall space required and improve the layout flexibility of the drive system.

Easier commissioning: The configuration wizard and GUI-based parameter configuration make commissioning and configuration easier and more convenient. Servo parameters can be conveniently copied from one drive unit to others through the bus, enabling one-off batch commissioning.

Simpler operation: In compliance with industrial Ethernet standards for automation, the following operations are supported: Use only a single cable to transmit user, process, and diagnostic data in real time. Upload and download data with one click (simultaneous upload and download supported without explicit restrictions). Read and write parameters through cascaded Ethernet ports. Import programming files through a PLC to implement one-touch programming.

03

Safety and reliability

Allows users to use the product in a more assured mode.

Built-in dynamic braking: In cases of servo faults, emergency stops, shutdowns, or motor brake failures, dynamic braking is activated to prevent device damage or physical injuries caused by rapid motor rotation, significantly enhancing safety.

Built-in temperature monitoring: Both the servo drive and servo motor support the temperature protection function to directly monitor the temperature status of the products through sensors. By doing so, faults can be detected or prevented at the earliest possibility, ensuring safe and reliable operation.

Harsh environment adaptability: The high protection design ensures stable operation even under harsh conditions.

STO integration: Electric shocks or mechanical injuries in fault conditions can be prevented without the need for output contactors.

Technical Data

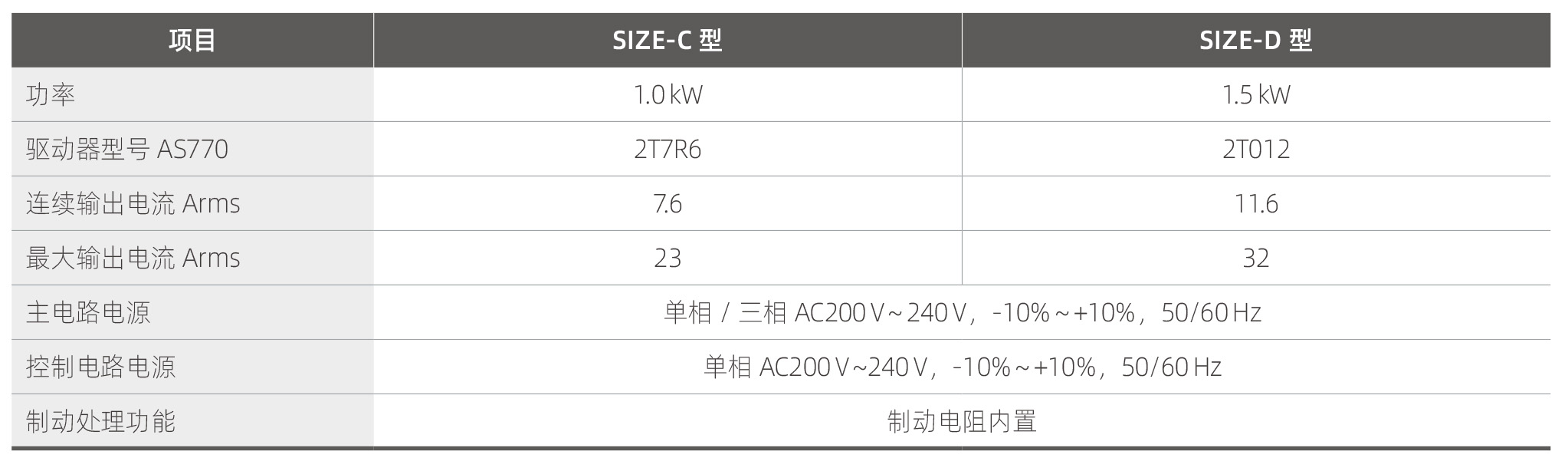

Single-phase 220 V servo drive

Three-phase 220 V servo drive

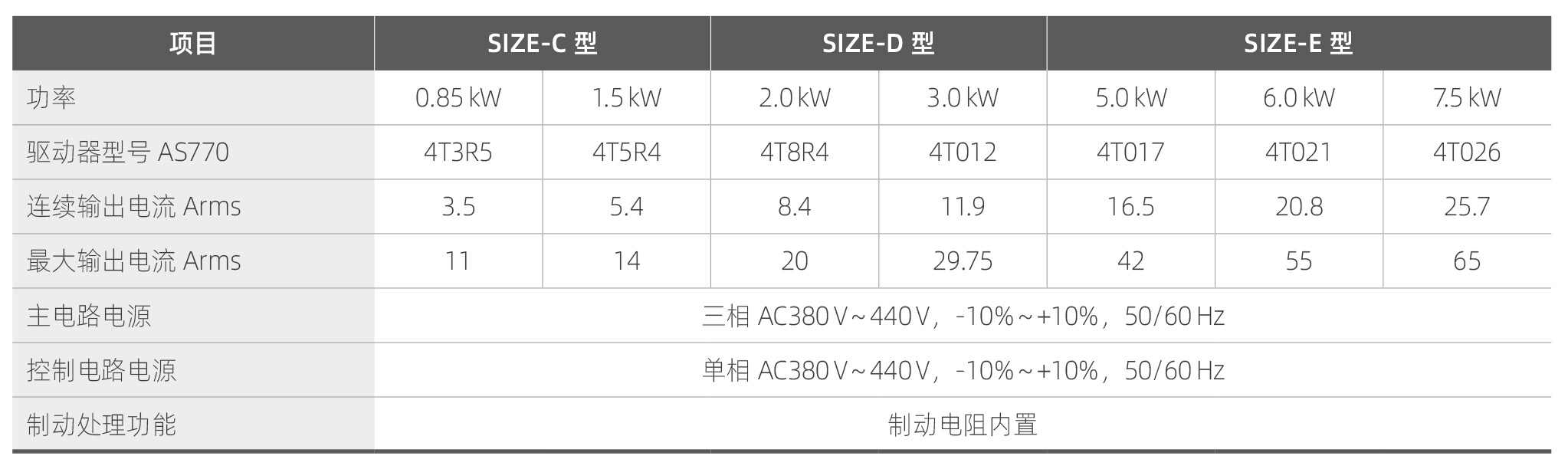

Three-phase 380 V servo drive

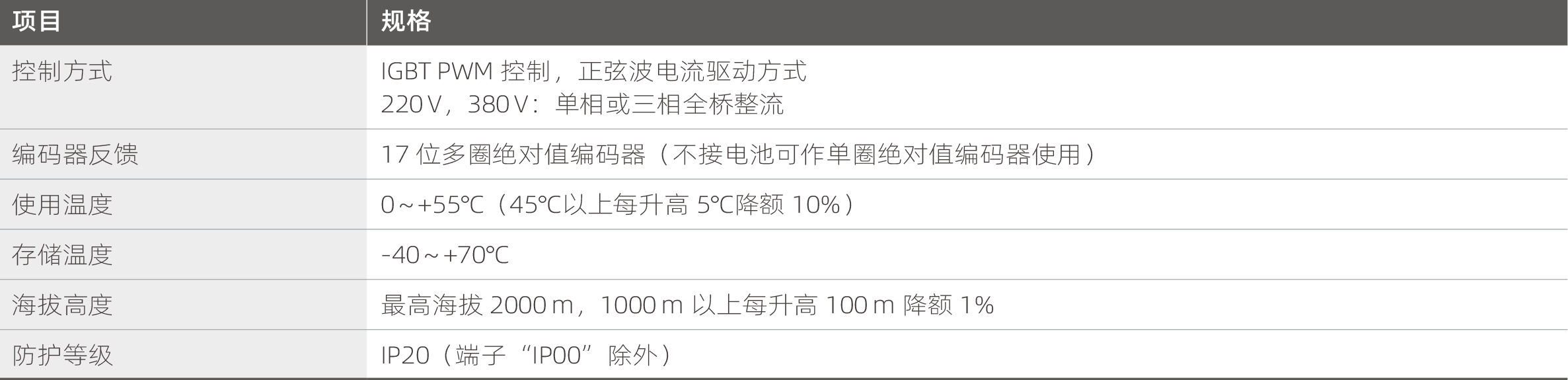

Basic specifications

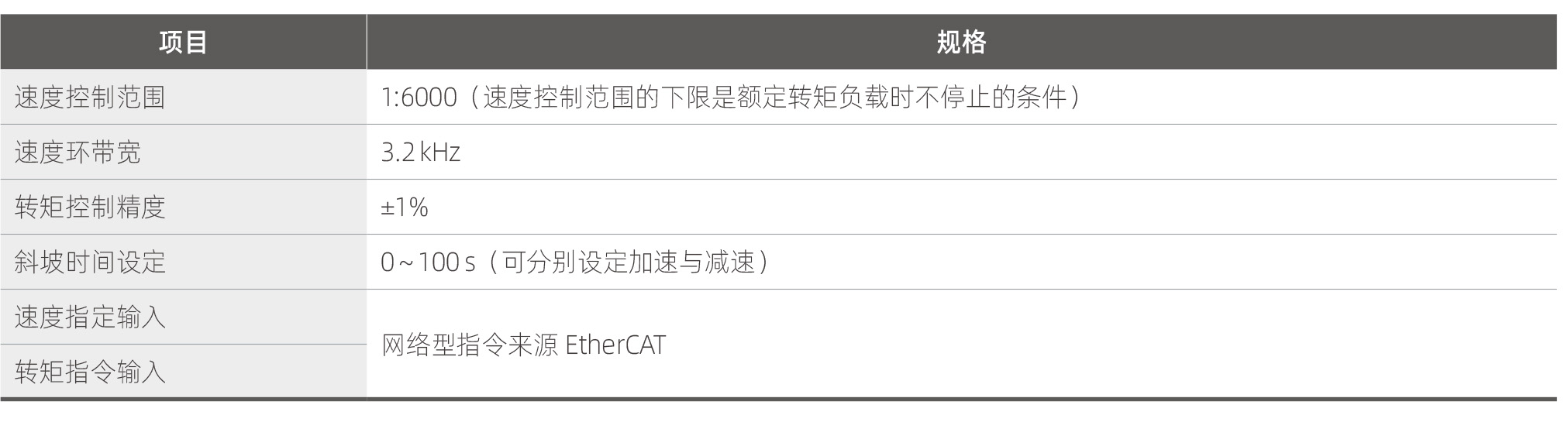

Speed/torque control mode

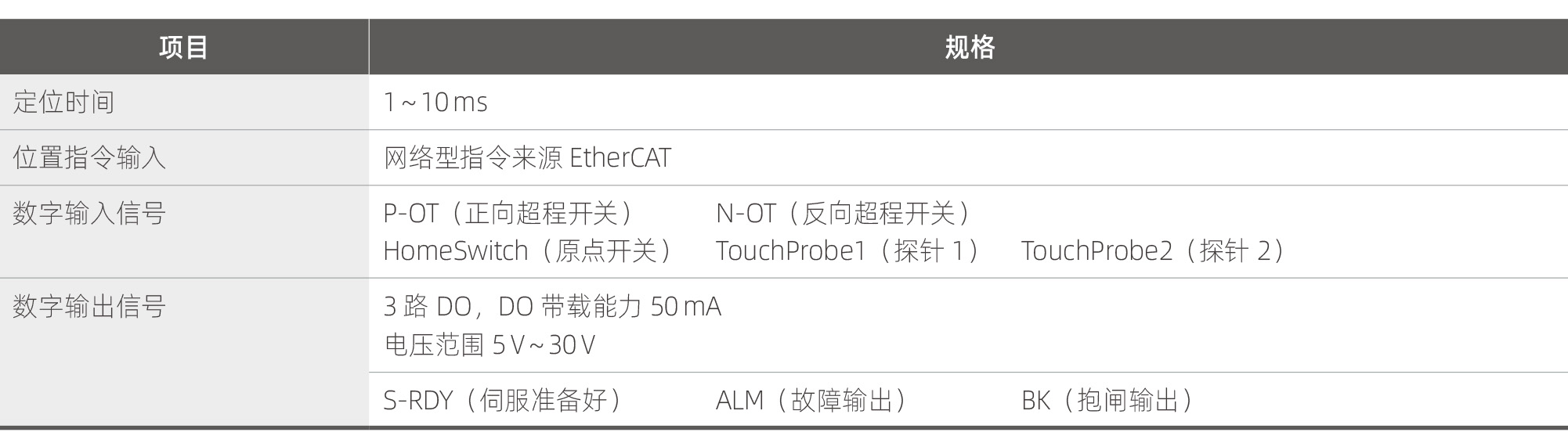

Position control mode

Built-in functions

Communication specifications

Downloads

Contact Sales

Contact Sales

We will contact you in a timely manner

Service Hotline

Service Hotline

400-112-1280

More contact information >

More contact information >